Ellesmere Zhu

As the E-cigarette Control Measures were officially implemented on October 1, 2022, tobacco flavor has become the only choice for domestic e-cigarettes in China. Meanwhile, on the other side of the globe in the US, a number of states and cities have banned flavored e-cigarettes; the European Union also proposed a draft ban on flavored heated tobacco products recently. The once wide range of flavored e-cigarettes is now rapidly narrowing, giving way to the traditional tobacco flavor, which is becoming mainstream.

The wave of tobacco flavor has put both juice and vapor core under the test. How to make the well-matched flavor that consumers are willing to buy is now a new challenge facing the e-cigarette industry.

Reproducing the taste of traditional tobacco in e-cigarettes is no easy matter, making it one of the major difficulties that many enterprises are working on currently. The key to emulating the flavor and taste of traditional tobacco is the vapor core, a core component of e-cigarettes. In this light, if a vapor core manufacturer wants to surmount the challenge, it must change its macro positioning and focus on hardware and software strength.

Technical problem: a "key" for an un-matched "lock"

In the face of the onslaught of the tobacco flavor wave, e-cigarette manufacturers have come up with their special ideas. Yet most manufacturers choose to rely on diluted tobacco flavors to help their fruit flavor-preferred customers through the transition period, which results in the homogenization of tobacco products.

To stand out in such a context, what characteristics must a tobacco-flavored e-cigarette have? Shenzhen Huachengda Precision Industry Co. Ltd.( hereinafter referred to as "Huachengda"), a global vapor core R&D manufacturer, gives the answer, that is, high recognition, rich fragrance, and superior taste are the key to building up memory points for customers, while dry burning, burnt core, condensation, and flying juice are the issues should be avoided.

Concept Photo of Huachengda's cotton products credit: Huachengda

Despite the clarity of thought and direction, there are still pain points for the vapor core of tobacco flavor, among which the instability is the major one, that is, the "key" often fails to match the "lock".

· Unstable assembly, which is determined by the structure and material of the vapor core;

· Unstable liquid discharge rate, which is the main reason for dry burning and burnt core;

· Unstable heating, which leads to inconsistency of the taste.

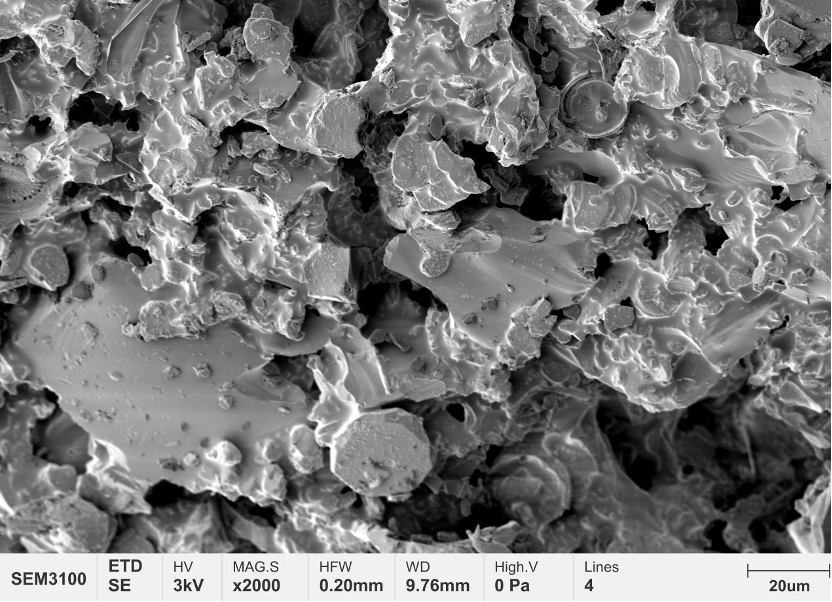

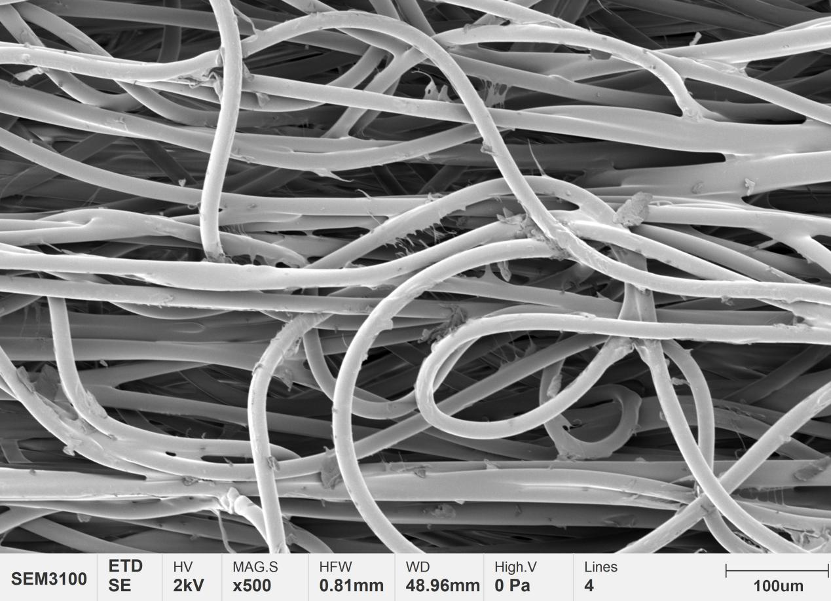

Taking the ceramic wick and cotton wick as examples, the current ceramic wick is hard and easy to assemble, though due to technical limitations, its texture is fine and the pore size is small, resulting in unstable liquid discharge as the juice with high viscosity cannot flow through smoothly. Contrary to the ceramic wick, the cotton wick is fully permeable and has a larger pore size, which allows the juice to pass smoothly (see Figure 2). However, for all cotton wicks offered in today's market, there is still a risk of being burnt in the core if the temperature is too high.

"There is a great difference between tobacco-flavored and fruit-flavored juice," said Chen Ping, CEO and chief engineer of Huachengda, "If we apply the vapor core designed for fruit flavor to tobacco flavor, the taste performance and characteristics of the core is completely different, really an unsatisfactory low reproduction of the tobacco flavor." Taking into consideration the difference between tobacco-flavored and fruit-flavored juice, Huachengda has optimized the tobacco flavor based on its original vapor core. "Ideally, different flavors of juice require different vapor cores, just like one key can only open one lock," added Mr. Chen.

Ceramic wick surface under electron microscope Photo credit: Huachengda

Cotton wick surface under electron microscope Photo credit: Huachengda

Empowering the Future with Technology: Exploring the "Third" Vapor Core

After upgrading the vapor core to solve the instability, here comes another new challenge for Huachengda, that is, how to make the tobacco flavor in the juice fully unleashed and more authentic.

To this end, Huachengda has invested a lot of effort. Mr. Chen said that optimization must be made to the structure, materials, formulations, and heating element of the vapor core. For example, the previous generation of vapor cores are heated by heating wires, so there will be overheating, scorching, and even burning off. However, the heating element made by heating mesh can heat the core evenly, thus making the smoke richer. Besides, it has a solid structure that is not easy to burn off, and with the increase in use time, the flavor can still be maintained at the initial level without any reduction.

Concept Photo of Huachengda's COTTONX credit: Huachengda

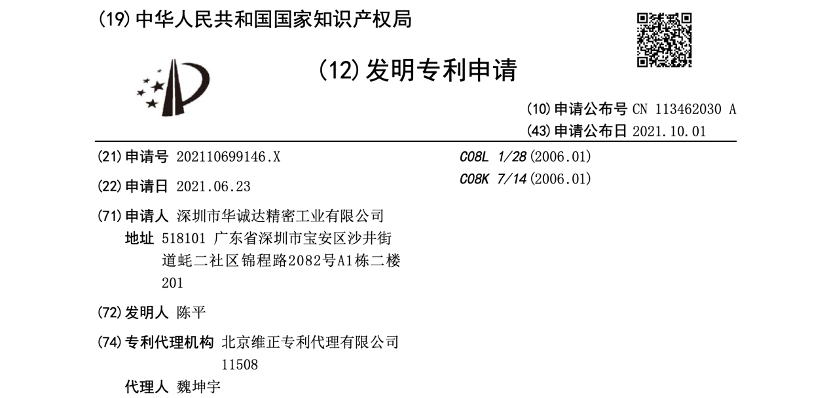

Keeping moving forward on the path of innovation, Huachengda has made dedicated research to see the birth of its new "fiber wick" and applied for a patent in 2021. The manufacturing of the fiber wick is mainly divided into two steps. First, break the fiber into pulp. Second, stick it with a binder. This can ensure the consistency of the material while improving uniformity, stability, and vaporization effect. Yet there is still room to improve this technology. After being mixed with the juice, the fiber wick will absorb the juice and expand gradually, which affects the liquid discharge speed. Therefore, more performance and material testing need to be conducted before wide application.

Now Huachengda's COTTONX and the fiber wick under development, one big and one small, can well complete each other and be respectively adapted to the use of disposable and reloadable product scenarios in the future.

Screenshot of Huachengda's patent application for its fiber wick

"Improving the user experience has always been the focus of the entire industry to develop," said Mr. Chen with an example, "Such as the juice storage cotton. It was originally designed to prevent juice leakage, but in real use, it would absorb a small portion of juice, which makes users feel that it is not worth the money. For e-cigarette makers, this is a spur to excellence.

"The development of the vapor core differs from that of the chip," concluded Mr. Chen, "For chips, from 10nm to 5nm to 2nm, the smaller the better. But for vapor cores, the development direction is still to be explored. We need to develop and customize the products according to specific laws and regulations and user needs in a decentralized manner. This means that only manufacturers with stronger R&D strength can go further with a large pool of technology reserves."

Exterior view of Huachengda, a global professional vapor core industry base Photo credit: Huachengda

Also read:

[Interview] HCD: From Cotton to Ceramics

*This article is an original article of 2FIRSTS Technology Co., Ltd. The copyright and license rights belong to the company. Any entity or individual shall make link and credit 2FIRSTS when taking actions to copy, reprint or distribute the original article. The company retains the right to pursue its legal responsibility.