Special Statement:

1.This article is a guest contribution reflecting the expert's personal views only and does not represent the official position of 2Firsts.

2.2Firsts has obtained authorization from the author to publish this article. Readers are advised to assess the accuracy, completeness, and reliability of the content and to treat the opinions and suggestions within with caution.

Author: Dr. Ren Yongli,Patent attorney of Beijing Lingzhuan Intellectual Property Agency Co., Ltd.

I. PMI’s TEREA Smoking Article and its Pain Point

In the novel tobacco industry, particularly in heated tobacco products (HTPs), Philip Morris International (PMI) is widely recognized as the most successful in both technology and commercialization. Its flagship products include the electromagnetic induction heating device (ILUMA smoking device) and its compatible consumable TEREA smoking article (hereinafter abbr. As TEREA STICK), as shown below:

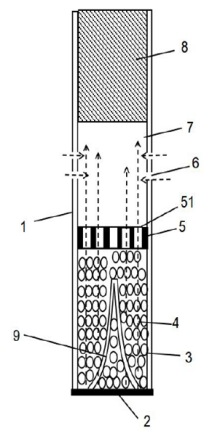

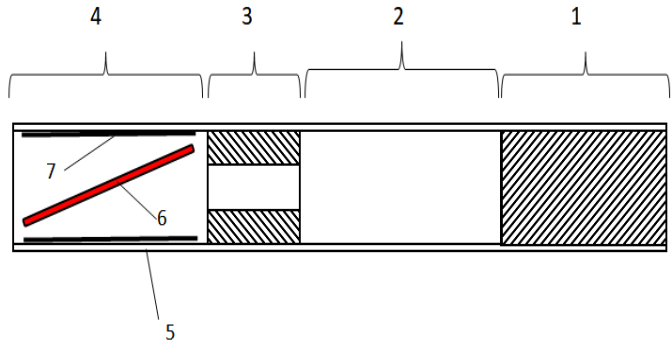

The TEREA STICK consists of the following sections from the distal end to the mouth end): front plug – smoking segment (tobacco material embedded with a susceptor sheet) – support segment – hollow segment – filter segment.

TEREA STICK have been extensively studied and imitated by other tobacco companies but have never been surpassed.

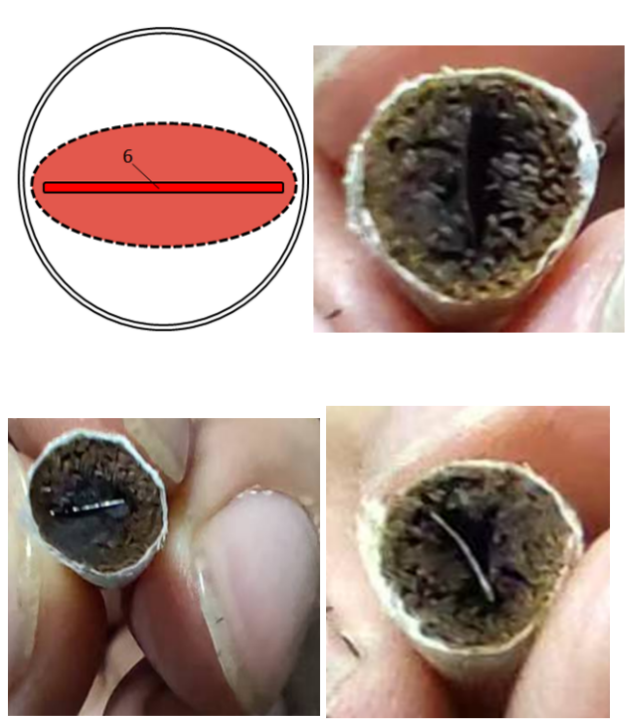

However, TEREA STICK is not without flaws. One key pain point is insufficient heating of the tobacco material due to the limited heating zone of the susceptor. The cross-section of the smoking segment of TEREA STICK after heated by an ILUMA device reveals that the effective heating zone is confined to the red zone enclosed by the dashed arc in the diagram below. Outside this zone, the temperature is insufficient, leaving much of the tobacco underheated. This results in inefficient utilization of the aerosol-generating material and reduced aerosol output.

This insufficient heating is a common problem in HTPs that adopt suscpetor central electromagnetic heating technology, whether the susceptor is embedded in the smoking article or housed in the smoking device and inserted into smoking article during heating.

Some HNB (Heat-Not-Burn) device manufacturers located in Shenzhen, P.R. China have addressed this pain point by developing peripheral electrical resistor heating device or infrared light heating devices, marketed as “ILUMA companions” . These devices allow for secondary heating and smoking of TEREA STICK after initial use with the ILUMA device. Tests show that such devices can achieve at least 8 additional puffs from an used TEREA STICK. These "ILUMA companions" have gained some accept in Japan market, appealing to cost-conscious smokers who seek to maximize tobacco material efficiency.

Are there other solutions? This article examines patents from various tobacco companies to explore potential answers.

II. Solutions Proposed by Other Companies

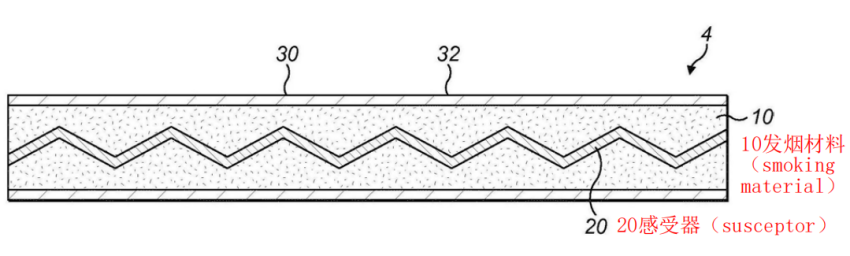

1. BAT’s Solution #1 – Curved or Folded Susceptor (Patent ’597)

Obviously a wavy or folded susceptor increases contact area with the tobacco material, expanding the effective heating zone.

Structurally, this aerosol-generating article can have a detachable mouthpiece, see the following figure, making it can be used both as a smoking cartridge (only a smoking section, without cooling section or filter section) compatible with a dedicated heating devices and as a smoking article (smoking section + cooling section + filter section) compatible with ILUMA devices:

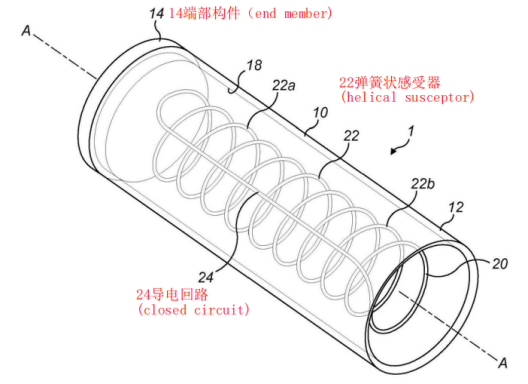

2. BAT’s Solution #2 – Helical Susceptor consisting a closed circuit to additionally provide Joule Heating (Patent ’601)

A spring-shaped susceptor enhances heating area with smoking material and enlarges the effective heating zone. Additionally, BAT designed the helical susceptor as an electrical circuit to introduce Joule heating alongside induction heating for improved heating performance.

However, the drawing of this patent showed below indicates that this design is a cartridge-only format (lacking a cooling section and filter section, so it can not be called “smoking article” because traditionally a heating smoking article should have a cooling section and filter section), making it incompatible with ILUMA device and requiring a proprietary heating device.

3. Shenzhen Company A’s Solution – V-Shaped Susceptor (No Patent)

Below is a cross-section view of the aerosol-generating-section of a smoking article produced by Shenzhen Company A , wherein the red V-shape indicates the susceptor.

This V-shaped susceptor increases contact area with smoking material but poses manufacturing challenges in continuous assembly of this smoking article because the V-shaped susceptor can hardly be incorporated into the smoking material in a continuous assembly process.

4. China Tobacco of Yunnan Industry’s Solution – Herringbone Susceptor (Patent ’057)

As shown in the figure below, the herringbone-shaped susceptor (9) increases contact area with the tobacco granules (4) while maintaining stable self-supporting positioning within paper tube (1) without requiring additional structural components. This design perfectly aligns with the technical requirements of "fill-type production" for a smoking article with granular tobacco as smoking material.

Additionally, this patent addresses the pain point of maintaining central alignment of the susceptor within the tobacco material. Taking TEREA STICK as an example, even if the susceptor is initially centered during manufacturing, external forces during transportation, storage and use often cause displacement from the central position, resulting in temperature gradients across the smoking section's cross-section. The patent solves this problem by designing the herringbone susceptor (9) with a maximum diameter equal to or slightly smaller than the inner diameter of paper tube (1), ensuring effortless and consistent central positioning.

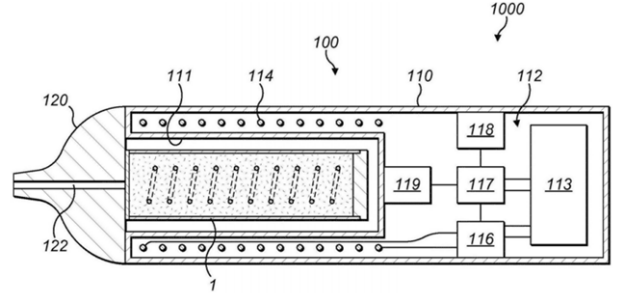

5. Shenzhen Company B’s Solution –Arc-Shaped Supplementary Heaters

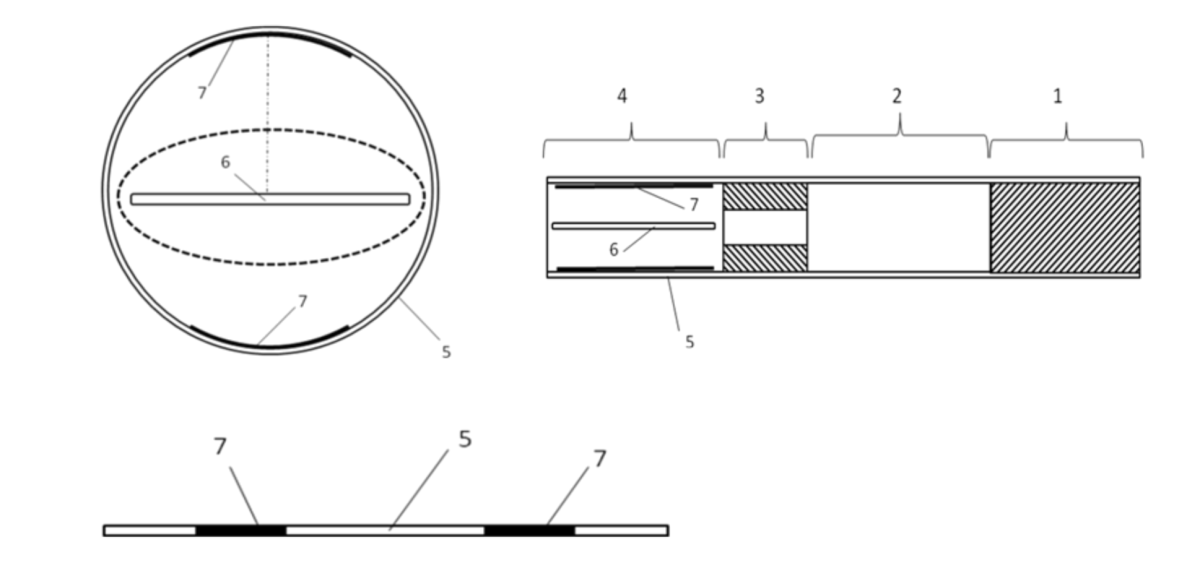

Some curved supplementary heaters can be positioned on the circumferential wall of the smoking article. As illustrated in the figure below, two arc-shaped supplementary susceptors (7) are incorporated on the inner surface of the cigarette paper (5), and their placement position enables heating of the aerosol-generating material located outside the effective heating zone of the central susceptor (6)【Patent ’861】.

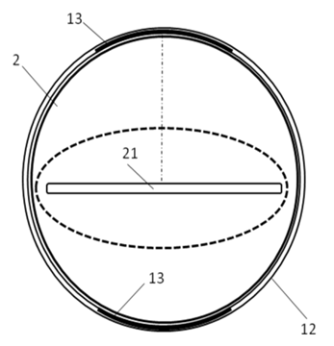

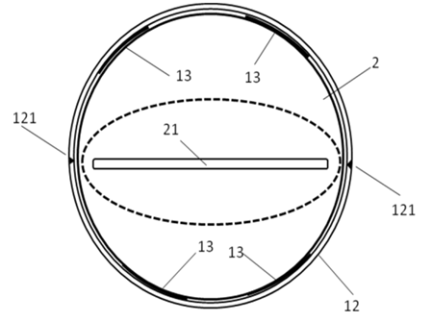

For optimal performance, discrete arc-shaped supplementary heaters (13) (either electromagnetic heaters or electric-resistor heaters) may be mounted on the inner periphery wall of heating chamber(12) of the smoking device's (externally to the smoking article (2)) to enable supplementary heating, as shown below 【Patent '007】.

A smoking article orientation indicator (121) located at the opening of the heating chamber (12) guides users to properly insert the early-generation TEREA STICK (which lack the front plug, allowing visual confirmation of the susceptor at the distal end of the STICK) into the heating chamber (12) by aligning the susceptor ends with the indicator during insertion. This ensures the arc-shaped supplementary heaters precisely heats the aerosol-generating material outside the effective heating zone of the central susceptor (21).

Shenzhen Company B's solution seems has notable merits because it is targeted and cost-effective, and corresponding patents have been granted. These patents can be the so-called "improved dependent patent" over PMI's core electromagnetic heating smoking article patents, potentially serving as valuable leverage for collaboration negotiations with PMI.

III. PMI’s Own Solutions

PMI has also realized the insufficient heating pain point of TEREA Stick and has provided some solutions as follows:

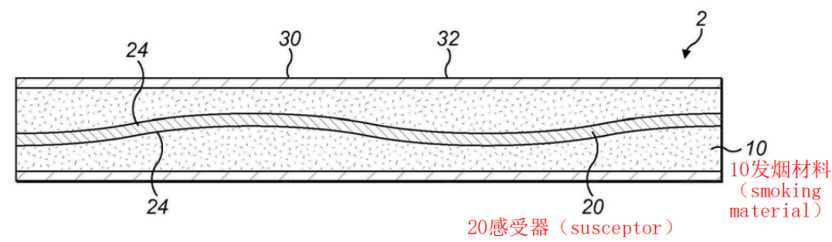

1. Multiple Susceptors (Patent ’880)

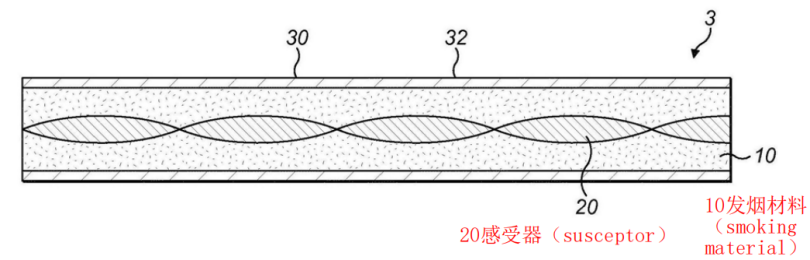

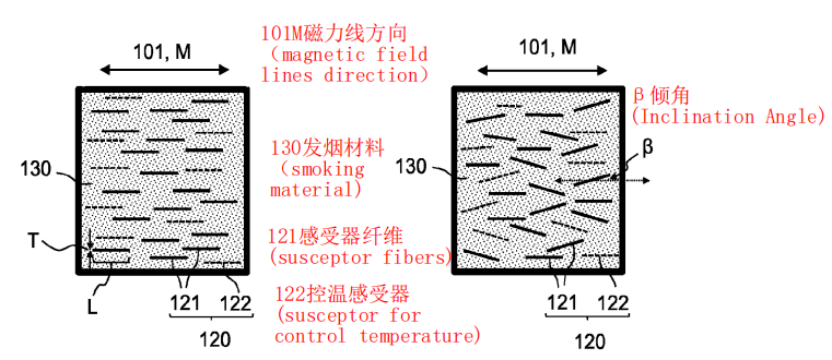

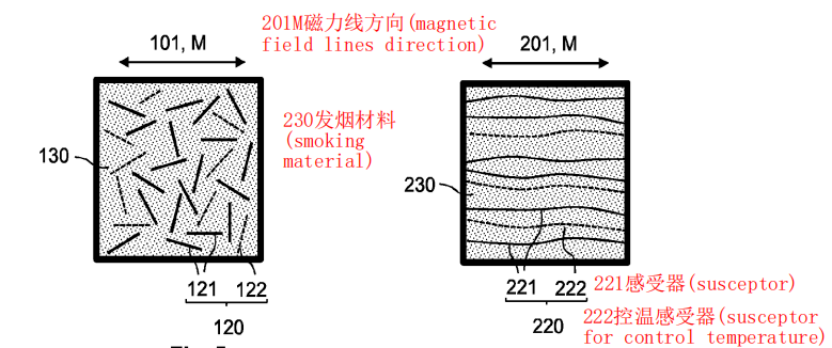

Compared with single susceptor, multiple susceptors can obviously increase the contact area with the smoking material. Even the multiple susceptors can have an inclination angle with the axis of the smoking article to further increase the contact area with the smoking material, as shown in the following figure:

Obviously, inspired by this patent, the single susceptor 6 can also be tilted as shown in the following figure. This obviously improves the heating efficiency. Although it is not convenient for industrial production, it is not ruled out that some manufacturers will use such a design. After all, the patent infringement risk of such a design is low, because most PMI patents require that "the receptors are basically arranged longitudinally in the smoking material section".

2. An elliptical cylindrical smoking material completed with an additional ceramic sleeve to form a cylindrical smoking article (patent ’955).

Since the effective heating zone of the central susceptor is in the shape of an ellipsoidal cylinder, it is better to wrap the smoking material around the central susceptor in the form of an ellipsoidal cylinder to make the two match. Then, the outermost part is filled with a ceramic sleeve to form a cylindrical appearance.

This solution obviously complicates the industrial production process and even makes continuous production difficult. Therefore, it is merely a theoretical solution on paper.

3. Front Plug on distal end of smoking article (Patent ’443)

This is the true solution adopted by the TEREA STICK currently sold by PMI. This front plug design can achieve multiple benefits at once, highlighting the extraordinary wisdom of PMI. The front plug not only prevents the susceptor from detaching from the smoking material, but also stops the crumbs and tar produced by the heated smoking material from leaking out from the distal end to contaminate the smoking article holding cavity. Objectively, it also plays the following three roles:

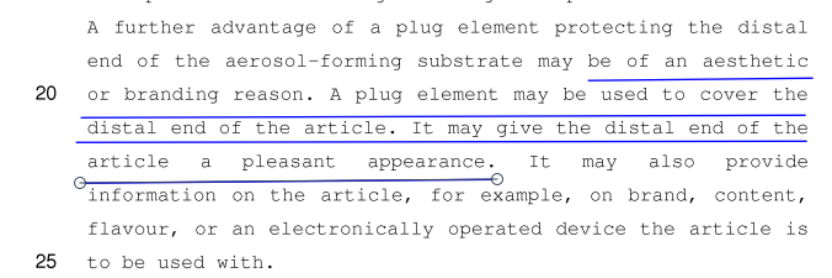

1. The front plug can cover the end face of the distal end of the smoking section, making it invisible to consumers and achieving an aesthetic effect (in other words, consumers are not bothered because the pain point is out of sight), as shown in the following patent statements:

2. The front plug also violates the using conditions of the Patent '007 for the arc-shaped supplementary heater developed by Shenzhen company B in point 5 of Section II of this article. Since the front plug covers the end face of the distal end of the smoking section, consumers cannot see the orientation of the central susceptor. Therefore, the smoking article orientation indicator 121 at the opening of the smoking article holding cavity of the smoking device using such arc-shaped supplementary heater loses its function. Consumers are unable to insert smoking article into the smoking article holding cavity in the correct orientation. It will be much more difficult for Shenzhen Company B to negotiate cooperation with PMI by using the "improved dependent patent" (but not completely impossible), after all, in the highly profitable HNB market, no manufacturer wants others to easily get a share.

3. The front plug also prevents the TEREA STICK (whether before or after being heated by the ILUMA device) from being heated by the "air-heating device" invented by Chinese companies. This is because the technical feature of "air-heating" is that the hot air heated to the smoking temperature enters from the distal end of the smoking article and heats the smoking material by air flow, carrying out the smoke. As the material of the front plug is acetate fiber, it is prone to being scorched by hot air at the smoke temperature, resulting in an unpleasant smell. Therefore, after the front plug is installed, consumers can no longer heat TEREA STICK with air-heating technology.

In conclusion, the front plug design of PMI seems not to actually solved the aforementioned insufficient heating pain point, but in fact, it has solved many other problems........

III. Future Outlook

It is believed that engineers in the HNB industry will come up with more solutions to address the pain point of insufficient heating of TEREA STICK. If a certain solution still has the potential for industrial production, its commercial value will be extremely huge, as it is expected to be used as a bargaining chip to negotiate cooperation with PMI.