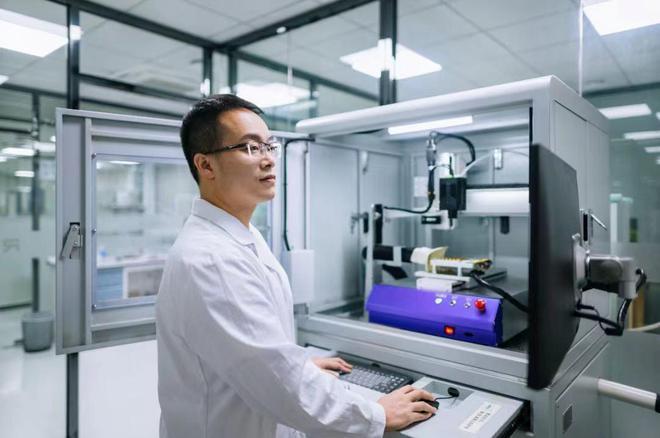

On August 2nd, a Blue Whale Finance journalist learned from RELX Yueke (Fogcore Technology) that its quality and safety laboratory in Shenzhen has received recognition from CNAS (China National Accreditation Board for Laboratories).

According to the information provided, CNAS (China National Accreditation Service For Conformity Assessment) is the English abbreviation for the China National Accreditation Committee for Conformity Assessment. Laboratories accredited by CNAS can issue testing reports that are recognized by more than 100 countries worldwide.

As per reports, the Yooz Quality and Safety Laboratory, mentioned earlier, was established in 2021 and covers an area of 450 square meters, serving as a key support component of the Yooz quality system. The laboratory focuses on testing the physical and electrical properties of products and is the second laboratory accredited by CNAS (China National Accreditation Service) within the company, Fogcore Technology. Yooz's first accredited laboratory, dedicated to testing e-liquid, was certified in August 2020, making it the first e-cigarette brand company to receive CNAS accreditation.

In fact, in daily use, electronic cigarettes in the hands of consumers are inevitably subjected to shocks and impacts, as well as challenges from wind, heat, and cold, with their durability and safety directly affecting the user experience. Therefore, in order to pursue top-quality products, YOOZ, in terms of quality and safety testing, has set up multiple tests including friction, drop, and high temperature in its quality safety laboratory. "At present, we have the ability to carry out testing in accordance with national standards," said Yang Yong, head of the YOOZ Quality Compliance Center. "In addition, we have also improved our testing standards by starting from many invisible details.

For example, YUEKE has an exclusively patented system for assessing suction noise, which helps quality engineers monitor the decibel levels of the sounds emitted during product use in real-time to reduce noise levels to the greatest extent possible and achieve "no disturbance" in terms of hearing. Meanwhile, the company also offers optional testing for cosmetics endurance. Engineers apply skincare products to atomizer rods and observe whether the product's appearance changes in high-temperature, high-humidity environments. This process can test the anti-corrosion abilities of different atomizer rods and identify the most durable products for users.

To address the widely-concerned issue of oil leakage, engineers conducted laboratory experiments simulating high-altitude pressures exceeding 3000 meters above sea level, testing atomized bombs. The tested products greatly mitigate oil leakage caused by changes in pressure.

In March of this year, national standards for electronic cigarettes as well as regulations for their management were issued, marking a move towards the legalization and standardization of the electronic cigarette industry. Yang Yong stated that Yooz will take on its quality responsibilities and strive for the highest quality, creating products that have a pure flavor.

It has been reported that YUEKE, since its inception, has invested a total of 800 million yuan in research and development, creating a matrix of eight large laboratories. In addition to the quality and safety laboratory, there are also innovation laboratories, chemical laboratories, life science laboratories, aerosol laboratories, atomization innovation laboratories, new material laboratories, sensory analysis laboratories, and after-sales testing centers. The quality system covers the entire user experience process.

According to Yang Yong, chemical laboratories can analyze the chemical components of aerosols and sprays, while life science laboratories are responsible for safety testing at the cellular and animal levels. By conducting multiple layers of testing, we ensure that the quality and safety of our products are implemented in every detail.

According to reports, the Yueke Chemical Laboratory tests 19 categories of 140 substances and 12 categories of 102 substances for aerosols. The Life Science Laboratory is capable of conducting six tests, such as cell toxicity, to further confirm product safety.

According to reports, Fogtech has recently been awarded the "License for Tobacco Monopoly Production Enterprise (Electronic Cigarette Product Production Enterprise)". Currently, the company is intensively developing new products that meet national standards, and some products have passed technical evaluations. In its statement, Fogtech said it will continue to aim for a perfect user experience and provide high-quality and reassuring products.

This article contains excerpts or reprints from third-party sources, whose copyright belongs to the original media and author. If there is any infringement, please contact us to delete it. Any organization or individual wishing to reprint must contact the author and refrain from reprinting directly.

This document has been generated through artificial intelligence translation and is provided solely for the purposes of industry discourse and learning. Please note that the intellectual property rights of the content belong to the original media source or author. Owing to certain limitations in the translation process, there may be discrepancies between the translated text and the original content. We recommend referring to the original source for complete accuracy. In case of any inaccuracies, we invite you to reach out to us with corrections. If you believe any content has infringed upon your rights, please contact us immediately for its removal.